Sharknose doors are generally created by routing a 45-degree bevel along one edge of a door/drawer front with a 90° Sharp Corner Tool.

To manufacture these doors, you must have the 90° Sharp Corner Tool in your toolset. If you are using a machine that needs a specific tool name, such as Biesse, you will need to follow the steps below to change the tool that is assigned to one that exists both on your machine and in your Mozaik ATC toolset.

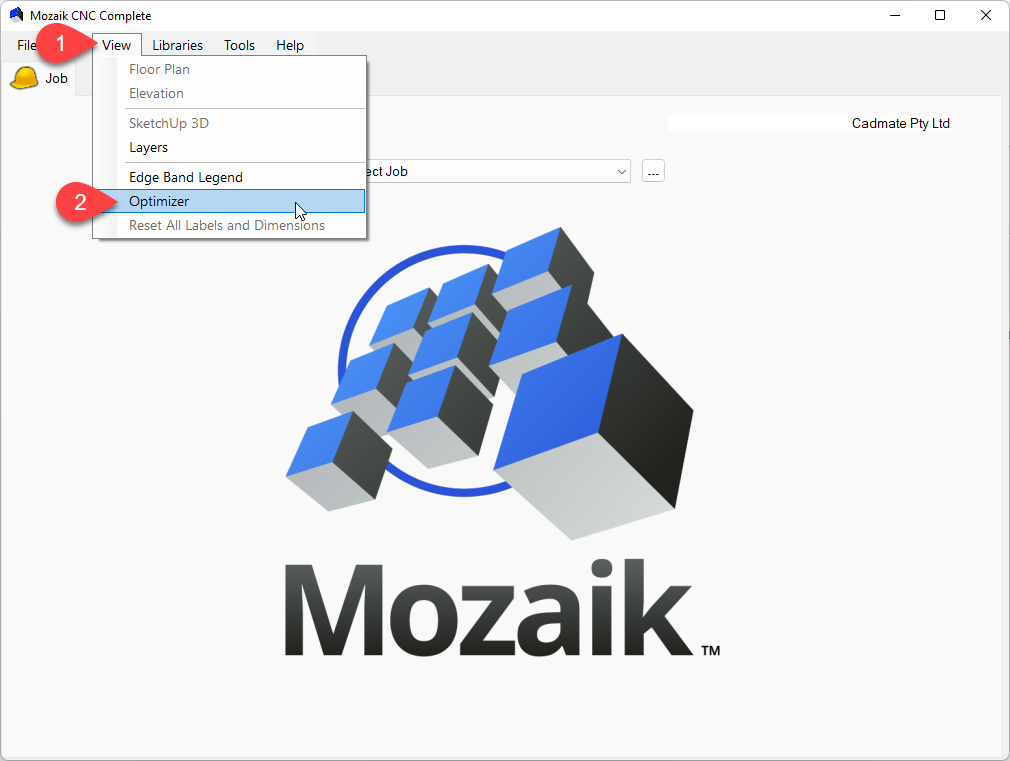

1. Open the Mozaik Optimizer by navigating to View

2. Click on Optimizer

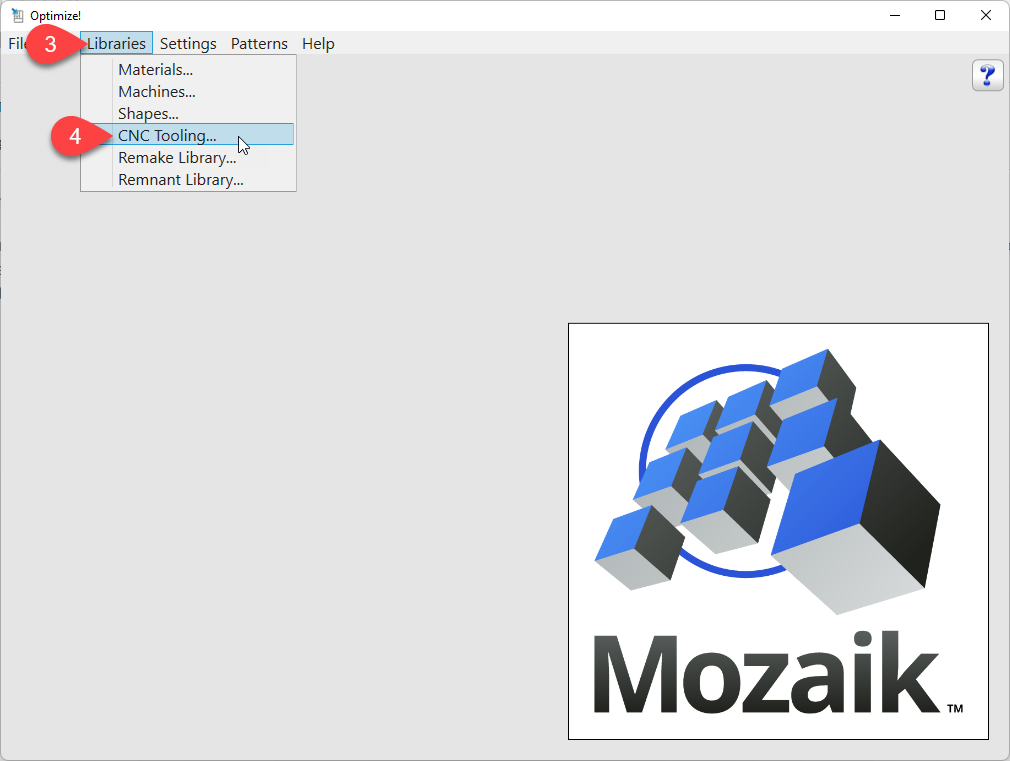

3. Select Libraries

4. Select CNC Tooling

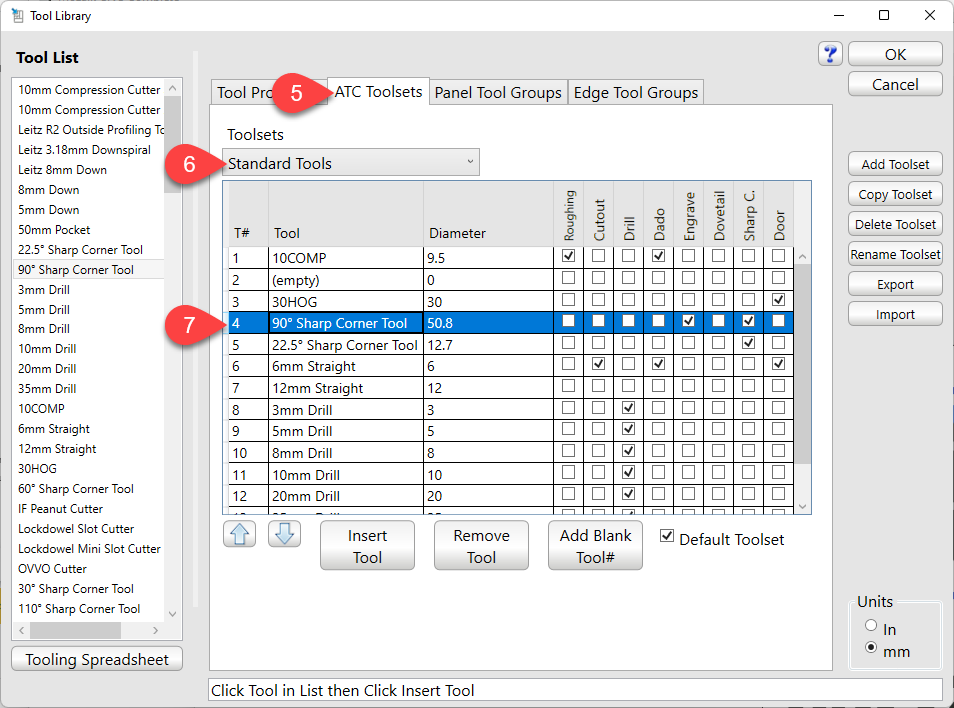

5. Naviagte to the ATC Toolsets tab

6. Select your Toolset (Note that this name will be different on everyone's machine)

7. Check you have a suitable tool loaded in your toolset, such as the 90° Sharp Corner Tool. As mentioned above, for a Biesse, this will be named something along the lines of 45V or V45 or VCUT (Check the name on your machine). Note the tool you would like to use on your Sharknose doors, as you will need it later in these steps.

8. Click OK, close out of the Optimizer and return to Mozaik.

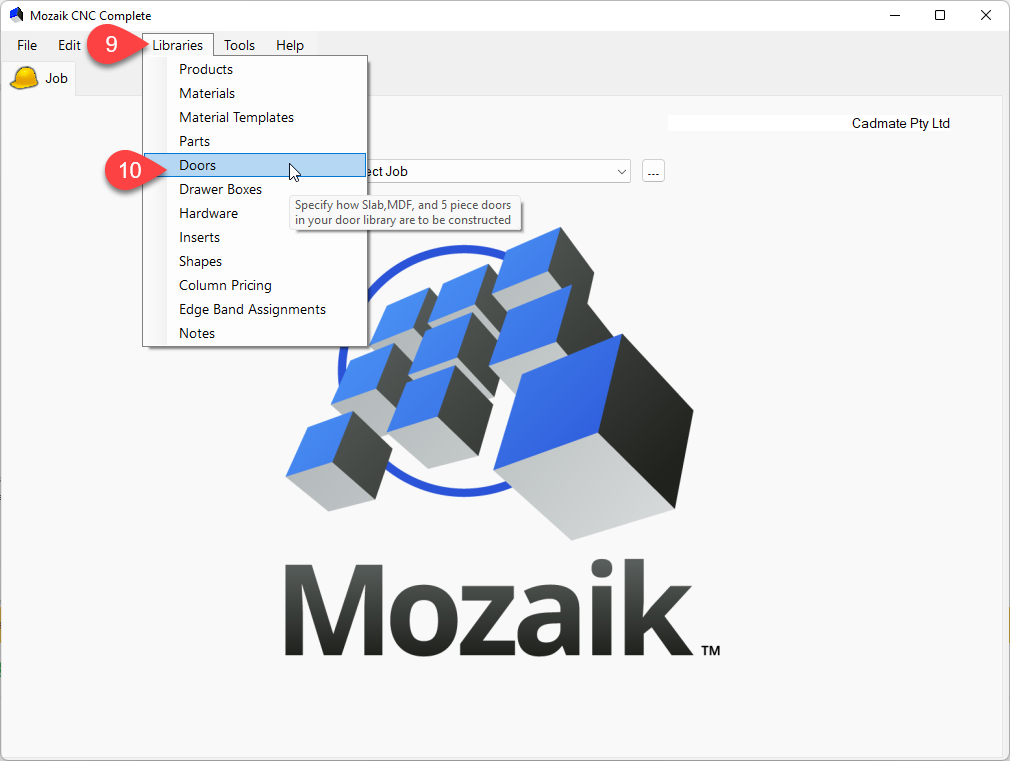

9. Navigate to Libraries

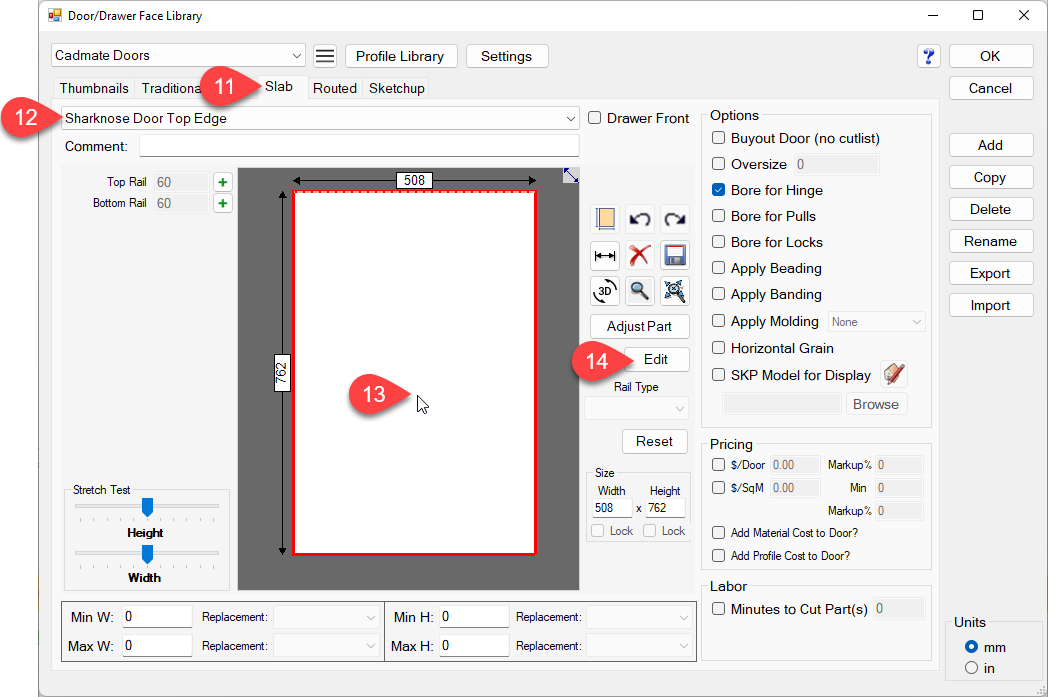

10. Select Doors

11. Select the "Slab" tab

12. Find your Sharknose Door in the list (there will be a few of them, and you will need to repeat the following steps for each door)

13. Click on the door

14. Select the "Edit" button

15. Select the "Operations" tab

16. Click the "Flip Shape" icon

17. Click on the Tool Path

18. Select the appropriate tool for your machine, as noted in step #7. In our example, we have assigned the 90° Sharp Corner Tool

19. Click OK

20. Repeat steps 12-19 for all the other Sharknose Doors in your library

You will now be able to visually see the shape of the bevelled edge (providing you have assigned the correct tool) and machine the doors.

Note: When machining the doors, you need to increase your part spacing to allow for the 90° Sharp Corner Tool diameter.